Belt Tensioner Kits

Belt Tensioner Kits

You are here::

BELT TENSIONER KITS

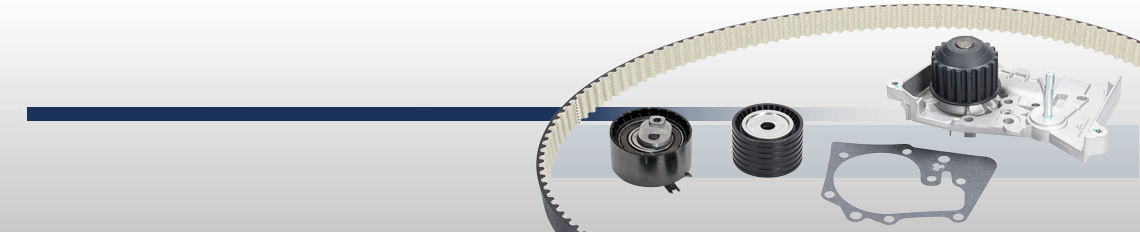

Belt tensioner kits contain high-quality bearings, pulleys and a sweep, which are all manufactured to guarantee a long service life. If possible, the belts are made of HSN (highly saturated nitrile) because this performs better in the high termperature areas of today’s engines.

The belt systems of modern vehicles undergo various stress factors e.g. high operating temperatures and a large number of revolutions per minute, high horse power loads, and narrow pulleys, which are used to save space under the bonnet.

All of our belt tensioner kits display the following functional characteristics: high load transmission capacities, optimised vibration and sound insulation, robust construction, resistance against cracks and wear and tear, high flexibility, working temperature range between – 40° C and +120° C, and a long belt service life. Our belt tensioner kits for belt drives and all accessories are made in accordance with the most up-to-date technology.

Our long-standing partnership with our manufacturers guarantees the highest quality and optimum performance from every single piece of tension equipment in our range.

The deflection pulley is firmly fitted and makes sure the belt closes around the driven pulley correctly. If the belt is driving more than one unit to facilitate auxiliary drive systems, belt tension rollers are used along the entire length in order to guide the belt and ensure constant tension. The profile of these rollers is often characterised by one or more V-shaped ribs. The belt tension unit guarantees that the belt is correctly tensed and guided. The tension can be adjusted upon assembly using an eccentric or a spring which operates on the clamping plate.

The automatic belt tension unit with integrated spring / absorber system ensures even belt tension when the engine is running.