Press

Press

You are here::

PRESS

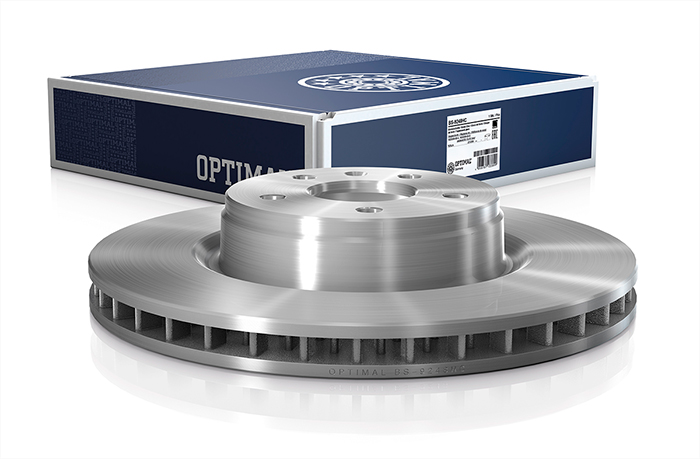

QUALITY BRAKE DISCS AND PADS WITH A HIGH STANDARD

30.04.2019

High-quality range of brake products completely revised and respecified.

Modern motor vehicles are subject to ever greater diversification in terms of their engines and chassis. This also has an impact on parts such as brake discs and brake pads, which are of particular relevance to a vehicle’s safety. The high demands in terms of material quality, handling and safety must meet the different requirements of not only the buyers but also the vehicles. With this in mind, OPTIMAL has now completely revised and respecified its range of brake products. In future, customers will be able to choose between coated brake discs, high-carbon brake discs and compound brake discs. The new brake pads from OPTIMAL now also feature an even more perfectly adapted friction lining compound for each class of vehicle.

Range of brake discs: coated, high-carbon or compound.

1. Coated brake discs

In future, the OPTIMAL range of brake products will only include coated brake discs. OPTIMAL uses a high-temperature resistant coating that provides reliable corrosion protection. But that’s not all, because coated brake discs from OPTIMAL not only impress with their easy handling and faster mounting (coated brake discs do not have to be degreased before installation), they also go perfectly with aluminum rims. Brake discs from OPTIMAL are therefore noted for their easy handling and optimum safety. For unambiguous part identification, they can be clearly identified by the prefix “BS”, a four-digit number, and a “C” in the item number (e.g. BS-8474C).

2. High-carbon brake discs

In addition to the wide range of coated brake discs, OPTIMAL now offers more than 300 high-carbon brake discs. These coated high-carbon brake discs have a greater carbon content. Due to their higher overall temperature resistance, high-carbon discs are also more resistant to deformation and lead to less “brake rubbing”. High-carbon brake discs from OPTIMAL offer optimum, vibration-free and safe braking. They are clearly identified by the suffix “HC” – for “high-carbon” – in the item number (e.g. BS-8474HC).

3. Compound brake discs

A decisive advantage of compound brake discs is that they are lighter than one-piece brake discs due to the carrier head being made of aluminum. Drivers of vehicles with compound brake discs fitted as standard will therefore not have to forgo their driving pleasure in the future either, because OPTIMAL’s high-carbon and coated compound brake discs enable OPTIMAL handling due to their lower mass compared to one-piece brake discs. They can also be recognized by the suffix “HC” for “high-carbon” and by the addition “compound” in the electronic catalogs such as TecDoc.

Brake pads have adapted friction lining compounds.

In addition to its range of brake discs, OPTIMAL has also revised and respecified its range of brake pads. The new brake pads feature improved and adapted friction lining compounds for the respective vehicle classes, which allow optimum braking distances in all conditions. Since they are also equipped with an anti-noise shim, they noticeably reduce noise when braking the vehicle. All brake pads are ECE R90 certified. In addition, the brake pads can now be clearly traced because each product has a batch code. Furthermore, each package has a special hologram seal. From now on, all OPTIMAL brake pads can be identified by a five-digit item number with the prefix “BP” – for “brake pad” – (e.g. BP-09540).

OPTIMAL AG & Co. KG will present the relaunch of its range of brake products for the first time to a wider public at the STAHLGRUBER shows in Munich (May 4-5, 2019) and Frankfurt (May 18-19, 2019). More information about the shows:

[Pictures: OPTIMAL AG & Co. KG]